Pulse jet bag filter

Product Details:

Product Description

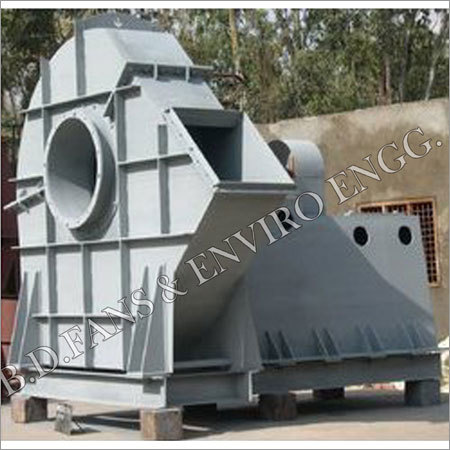

Pulse Jet Bag FilterB.D.FANS Bag filters are available in different designs, suitable for various application and purpose.All these bag filters are designed on latest technology for high collection efficiency minimum space requirement, trouble free operation low cost and high life. These bag filters have found their application in high pollutant industries.

We manufacture pulse in jet type bag filters which provide as a economic mode of dust collection for various presses operation, these are simple in design with no internal moving parts. They offer trouble free operation with compressed air jet cleaning. There method of cleaning operation at high filter rates resulting in compact unit occupying less floor space.

Capacity ranging from 500m3/hr to 4,50,000m3/hr.

Online Pulse Jet Bag Filters

In an online bag filter, bags are cleaned row by row, even when the dust laden gas is filtered. The sequence of cleaning is controlled automatically by a sequence controller. This operates the assembly of solenoid and pulse valves which direct the air flow into the manifolds. The holes are jig drilled for perfect alignment with the venturi centre for achieving maximum cleaning efficiency.

These include:

- Lower pressure drop across the unit

- Lower consumption of cleaning compressed air

- Longer filter bag life

- Lower noise level during operation

The low pressure cleaning system uses a special immersion type header mounted pulse valve, as shown in picture 1 below.

This system is designed to achieve:

- Highly efficient & quick pulse of cleaning air

- Lower pressure drop of cleaning air due to elimination of bend in pulsing system

Offline Pulse Jet Bag Filters

This mode incorporates the advantages of pulse jet bag filters, as well as that of a reverse air bag house. Each compartment is similar to an online pulse jet bag filter. The cleaning process consists of sequentially isolating each compartment and cleaning it with compressed air. All compartments are then cleaned automatically. Offline cleaning is suitable for light and fine dust, and for larger volumes where the occurrence of fluidization is a distinct possibility.

The offline bag filter contains 4 to 6 bag filter compartments. Each compartment is similar to online bag filter. Gas flow through a compartment is stopped temporarily when the pulse cleaning of the bags is to be done. The dust dislodged from bags settles quickly in the hoppers because of absence of gas movement in the bag filter compartment. During this time the remaining compartments keep filtering the gases as usual. Each compartment is cleaned one after another in same manner.

The starting and stopping of gas flow through individual compartments is achieved through a compact pneumatic damper system. Generally the offline bag filter is employed for larger gas volumes.

Product details

| Fan Power | 15 KW |

| Filtering Area | 90 m2 |

| Finish | Painted |

| Installation Method | Vertical |

| Surface | Color Coated |

| Frequency | 50-60 Hz |

| Material | MS |

| Brand | B. D. Fans And Enviro Engineering |

| Efficiency | 99% |

| Usage/Application | Industrial |

Other Products in 'Pulse Jet Bag Filter' category

|

B.D. FANS & ENVIRO ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |